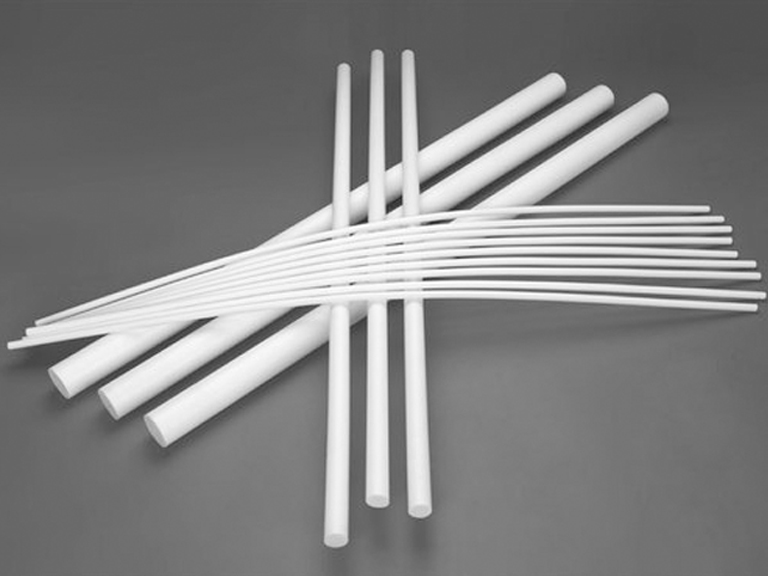

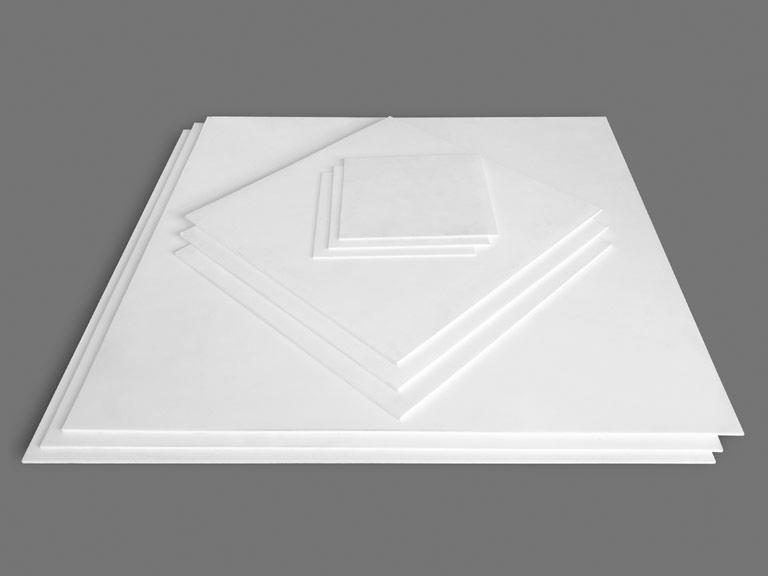

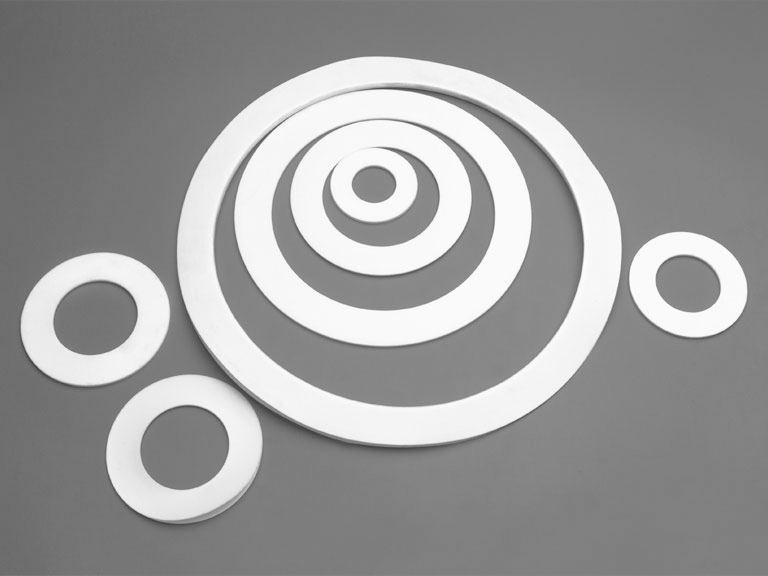

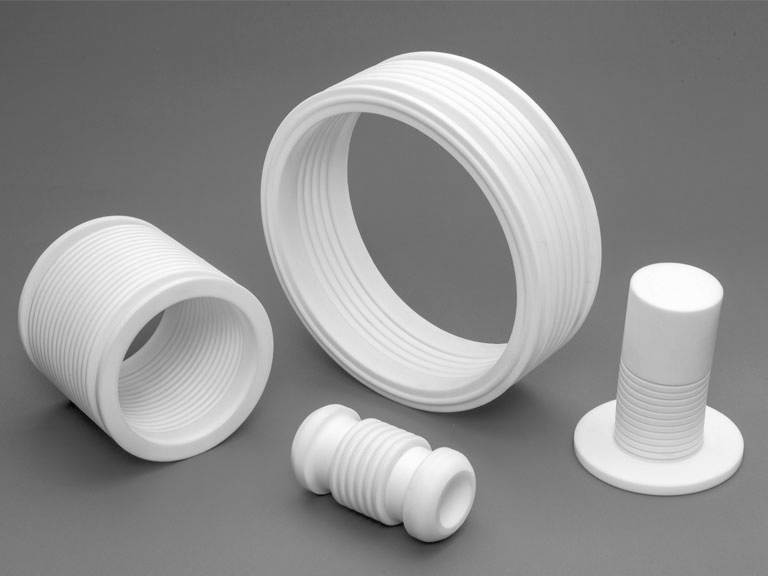

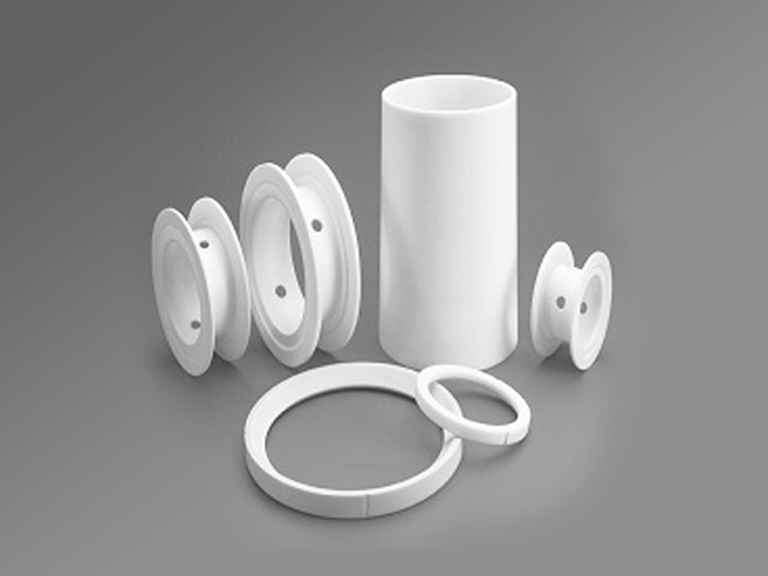

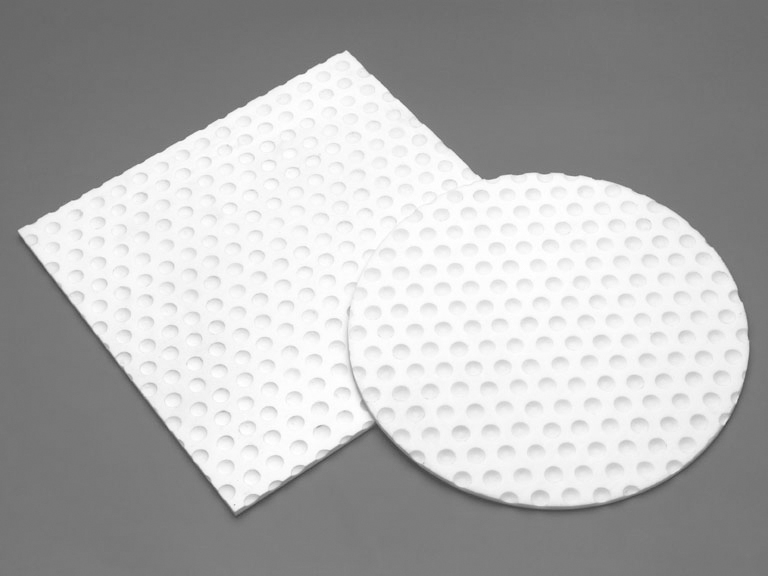

Standard Fluoromers Pvt. Ltd. is India's premium quality manufacturer & major exporter of PTFE & filled PTFE products such as PTFE Rods, PTFE Bushes, PTFE Moulded Sheets, PTFE Skived Sheets, PTFE Pipes, PTFE Tubings & PTFE Machined Products such as PTFE Gaskets, PTFE Valve components, PTFE Bellows in variety of grades such as Virgin PTFE, Glass Filled PTFE, Carbon Filled PTFE, Graphite Filled PTFE, Bronze Filled PTFE, PEEK Filled PTFE & Chemically Modified PTFE and Custom grades.

High Performance Properties of Polytetrafluoroethylene PTFE -

High Performance Properties of Polytetrafluoroethylene PTFE -

Polytetrafluoroethylene - PTFE is high performance engineering polymer having versatile properties such as:

Chemical Inertness

Chemical Inertness Exceptional weather resistance

Exceptional weather resistance Excellent electrical insulator characteristics

Excellent electrical insulator characteristics

Heat resistance

Heat resistance Non-adhesive Properties

Non-adhesive Properties Very low coefficient of friction

Very low coefficient of friction

Properties of PTFE

Grade of PTFE & Filled PTFE

Virgin Grades of PTFE are available as per ASTM standard number 4894 such as Premium, Standard, General & Filled grades of PTFE as per ASTM standard number 4745 such as Grade 1 : 15% Glass filled PTFE, Grade 2 : 25% Glass filled PTFE, Grade 3 : 35% Glass filled PTFE, Grade 4 : 5% Glass and 5% MoS2 filled PTFE, Grade 5 : 15% Glass and 5% MoS2 filled PTFE, Grade 6 : 10% Graphite filled PTFE, Grade 7 : 15% Graphite filled PTFE, Grade 8 : 25% Carbon and Graphite filled PTFE, Grade 9 : 32% Carbon and Graphite filled PTFE, Grade 10 : 40% Bronze filled PTFE, Grade 11 : 60% Bronze filled PTFE, Grade 12 : 55% Bronze and 5% MoS2 filled PTFE, Grade 13 : 50% Stainless steel filled PTFE.

Super-Speciality Grades of Filled PTFE -

Standard Fluoromers Pvt. Ltd. Manufactures PTFE Products in Super-speciality Filled grades such as Antistatic PTFE, Conductive PTFE, Peek Filled PTFE, Alumina Filled PTFE, Calcium Fluoride Filled PTFE, Silica Filled PTFE, Ceramic Filled PTFE, Mica Filled PTFE, Aromatic Polyester - (Ekonol ®) Filled PTFE, Polyimide Filled PTFE, Stainless Steel Filled PTFE, Boron Nitride Filled PTFE, Mineral – Wollastonite - Calcium Silicate Filled PTFE, Barium Sulphate Filled PTFE, Polyphenylene Sulfide - PPS - (Ryton ®) Filled PTFE, Silicon Carbide Filled PTFE, Copper Nickel Filled PTFE – for critical service conditions & specific applications

Brand Equivalent PTFE Products -

Standard Fluoromers Pvt. Ltd. Produces PTFE products equivalent grades & brands such as Rulon ® AR, Rulon ® LR, Rulon ® J Gold, Fluorogold ®, Turcite B ®, Fluorosint ®, based on customers requirement for specific application & service condition.